- May 6, 2020

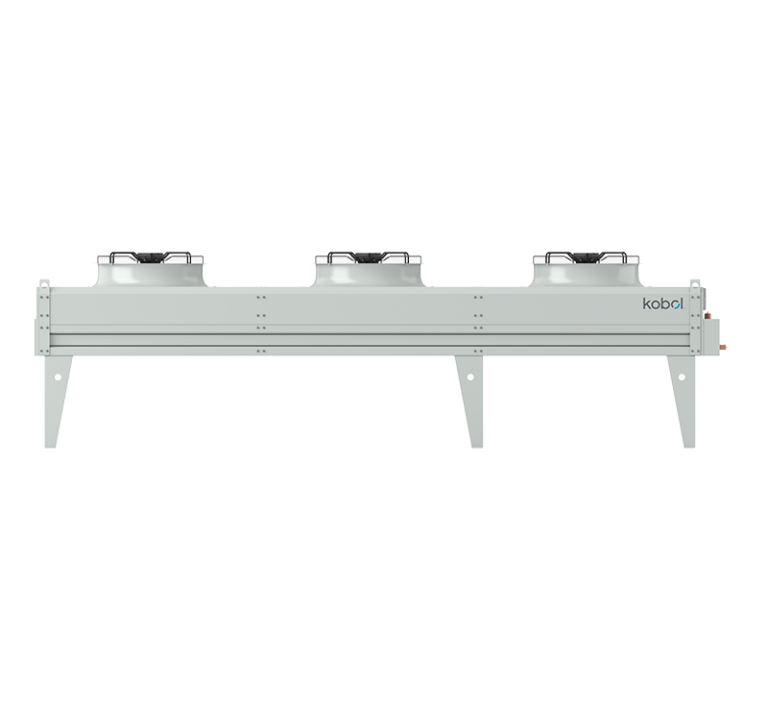

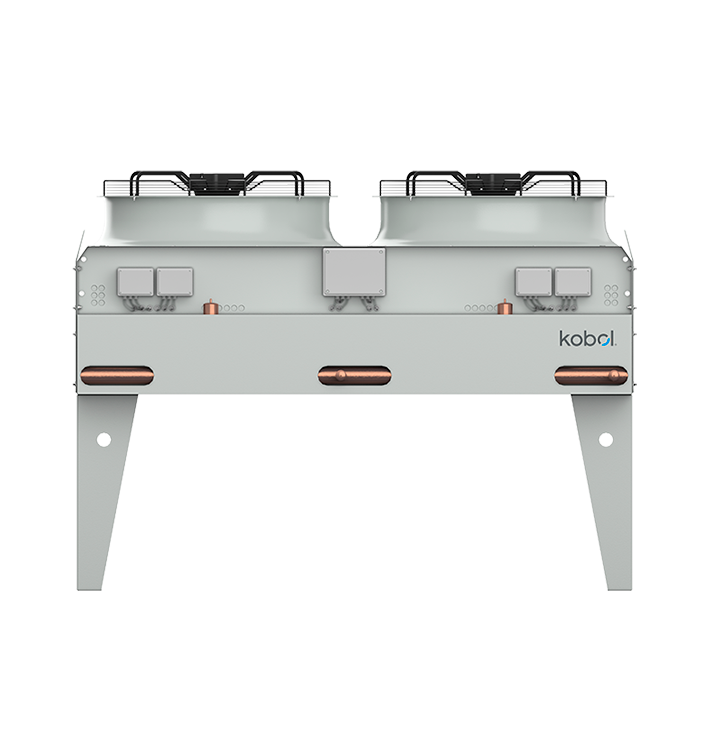

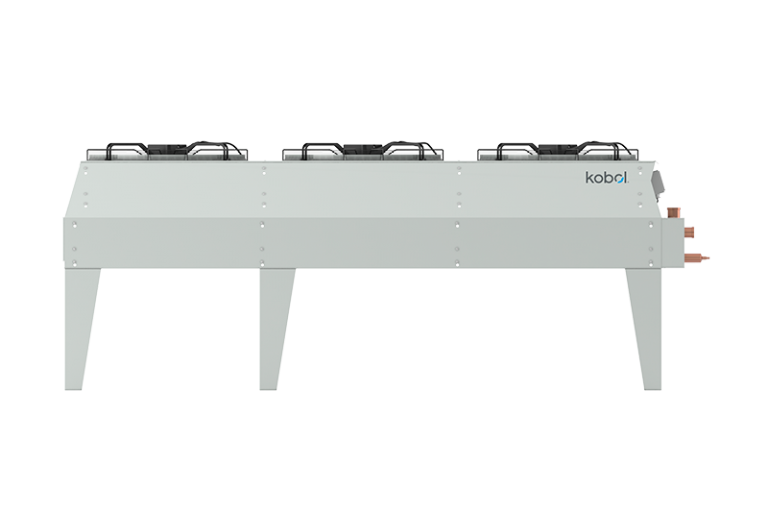

TRANSCRITICAL AXIAL (KGX 630 – KGX 910)CO2 GAS COOLERS

REMOTE INSTALLATIONS

This line of product, ready to use in CO2 transcritical intallations, consists of 90 models of axial gas coolers for industrial applications, available in cooling capacities between 50 and 1.200 KW.

Koxka’s gas coolers present a low noise level and a minimum energy consumption. All models are fitted with EC fan motors as standard. The speed of its fans can be controlled electronically to increase the energy savings.

The KGX-630 range has models with capacities from 13 kW to 285 kW. Likewise, the KGX-910 range has models with capacities from 30 kW to 1.100 kW.

- Finned coils

Built with K65 copper tubes Ø 3/8″, manufactured in compliance with the CUPROCLIMA specifications. The staggered arrangement of copper tubes across self-spaced fins, the accurate link between tubes and fins as well as the use of corrugated fins, all of this configuration allows our coils to reach the highest performance.

All coils are subjected to a resistance & leakage test under a rated pressure of 175 bar and pressurized using nitrogen at 1.5 bar in order to avoid the corrosion of the inner surface of the copper tubes.

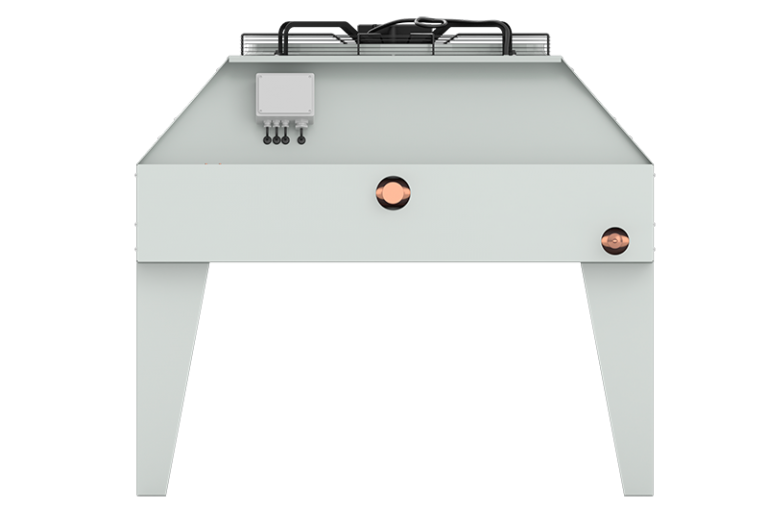

- Casework

The case structure of the unit cooler is manufactured in galvanised steel.

Its external surface is epoxy-polyester painted and then baked and cured at 180ºC giving it a high protection against corrosion even in extreme environmental conditions.

Internal separators to avoid the “by-pass” effect during sequential operation of fans.

Metallic protection on connections and return bends.

LEVITOR SYSTEM, system that levitates the coil in order to avoid leaks.

KGX-910 include legs for both positions (500mm/type 1 – 1150mm/type 2), for KGX-630 legs for vertical position are included (740mm/type 2).

- Fan motors

Fans’ diameter is Ø 630 mm (KGX-630) and 910 mm (KGX-910)

Axial fans with external rotor (380-480V III @ 50/60Hz).

Equipped as standard with EC fan motors. These fans can modulate the rotation speed depending on requirements, with excellent acoustic performance. Providing the optimal operation of the installation.

- Construction

For vertical air inlet (V-V), and horizontal air inlet (H-D).

- FIN MATERIAL

- Copper Fins

- Coated Fins

- CASING

- Legs (KGX-630 horizontal)

- Legs 800 or 1.000 mm. (KGX-910 horizontal)

- Stainless steel

- ELECTRICAL OPTIONS

- AC fans

- Wiring into centralized box (included with EC Fans)

- Shielded Wiring

- Switch on/off

- Axitop

- OTHER

- Blygold

- Spray adiabatic system

- Box

- Semihermetic or Scroll

- Scroll: Normal or Acoustic Isolation