- June 16, 2016

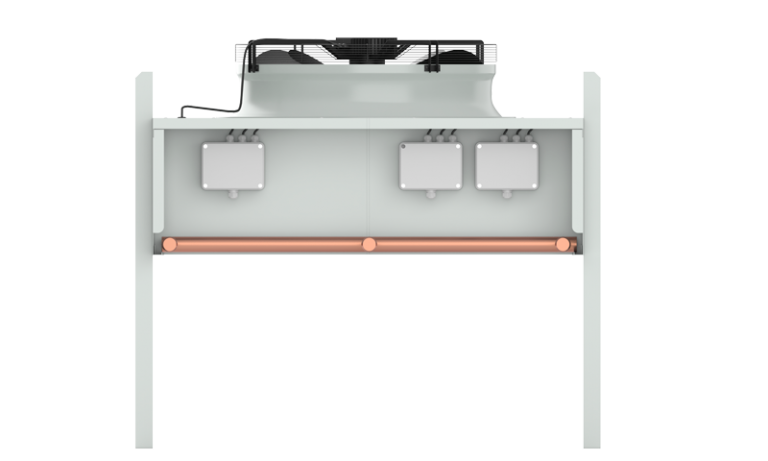

Micro-channel coils:

Built with aluminum tubes with a 25mm width, and winnowed aluminum fins. Zinc coated fins and multi-port tubes are manufactured with alloys specially developed for this technology and flux-welded in an inert atmosphere to create a homogenous chemically steady assembly with leakage-free joints, which guarantee improved corrosion resistance of the condenser unit. In addition, by using only Aluminum to manufacture our condensers, they are 100% recyclable. This greatly reduces its environmental impact.

Every coil has passed a leakage test under a rated pressure of 3,923 kPa (40kg/cm2) and pressurized using nitrogen at 147 kPa (1.5kg/cm2) in order to avoid the corrosion of the inner surface.

Casework:

The case structure of the cooling unit is manufactured in galvanized steel; its external surface is finished in epoxy-polyester and then baked and cured at 180°C, achieving a high protection against corrosion even under extreme environmental conditions.

Fans and motors:

Fans have a 500 and 630 mm diameter (depending on the model) and they are equipped with external rotor single-phase motors (230V @ 50Hz) or three-phase motors (400V @ 50Hz) (depending on the model).

Every model is equipped with high-efficiency EC fans. In addition, the electrical connections are included.

Assembly:

For vertical air inlets (V-V) or horizontal air inlets (H-l), to be specified on the order.

Casing

- Legs

Electrical Options

- Shielding

- Isolator Switch

Other

- Blygold treatment

[rev_slider alias=”producto-microcanal-axial”]