- March 15, 2018

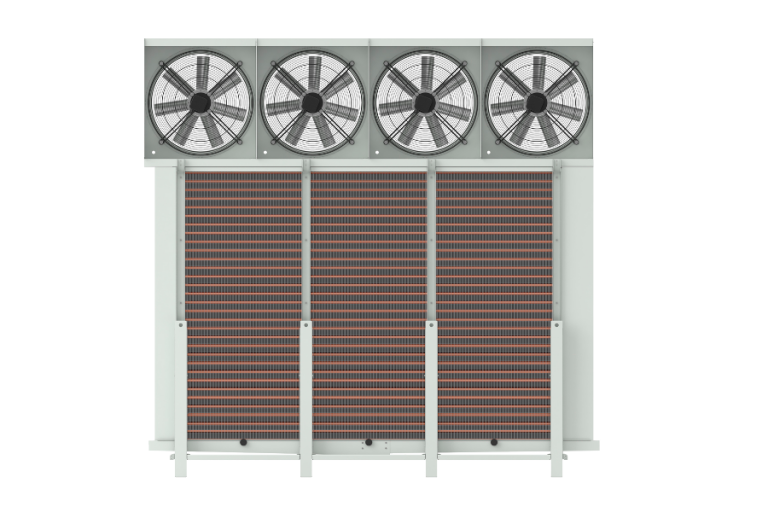

BLAST FREEZER (KEB-KEV)EVAPORATORS

QUICK COOLING PRODUCT APPLICATION AND FROZEN PRODUCT APPLICATION

Range composed by 19 models, specially designed for quick cooling product application and frozen product application, requiring a good distribution of air with maximum use of space.

The main advantage off ered by our equipment, is a fast and homogeneous process that causes the formation of small ice crystals, which allows the cells of the food to spoil much less. In this way, when you get time to thaw, preserve much better the original properties of the product.

- Finned coils:

Constructed using inner grooved copper tubes Ø 5/8” diameter, manufactured according to CUPROCLIMA® specifications, and aluminium corrugated fins.

The parallel arrangement of the copper tubes across self-spaced fins, the accurate link between tubes and fins as well as the use of corrugated fins allow our finned coils to reach high performance.

The different fin spacings are 7 mm and 10 mm.

Every coil has been subjected to a leakage test under a rated pressure of 40 bars and then pressurised using nitrogen at 1.5 bars approx. in order to avoid the corrosion of the inner surface of the copper tubes.

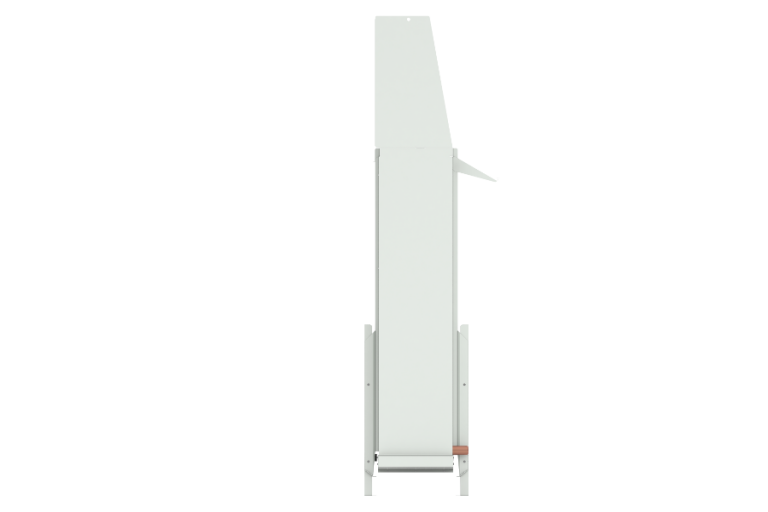

- Casework:

The metal casing work is manufactured in galvanised steel. Its external surface is painted epoxy-polyester and then baked and cured at 180ºC (365ºF), giving it a high protection against corrosion even in extreme environmental conditions; moreover this casing allows to meet more demanding food hygiene standards.

Includes double drip tray to make the drainage of the water (resulting from defrost) easier.

For better maintenance the drip tray and endplates are readily dismounted from the casework giving an easy and fast access to the inside of the unit cooler.

- Fans and motors:

Fans’ diameter are 500 mm or 630 mm (depending on model), blowing fan (KEB) and sucking fan (KEV), in those models three-phase motors (400 V / 50Hz)

Painted fan guards are made of zinc plated steel wire and support a water tight terminal box where the fans’ motors are wired.

- Defrost:

The heaters are shielded by a stainless steel tube and their terminals are vulcanised over it to avoid electric shunts; every heater includes a single ground wire.

They are strategically located across the finned coil in order to provide suitable and uniform defrosting.

- Fin Material

- Copper Fins (only fi n spacing 7mm)

- Coated Fins

- Casing

- Stainless Steel

- Side protections

- Separate ventilation kit (Only KEV range)

- Defrost

- Hot gas defrost

- Hot gas defrost in coil and electric in tray

- Electric defrost

- Water defrost

- Fan ring heater

- Other

- Blygold

- 60Hz Fans

- Refrigerants

- R134a, R404A, R407F, R448A, R449A, R452A…

- Water Glycol – CO2